All of our components are made of high quality materials; the specifications for the respective components can be viewed here:

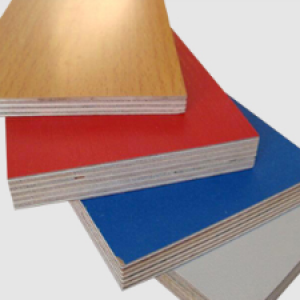

The wood used for our equipment is high quality softwood, dried to a 16% degree of wetness, glued together in layers with no wood core, and diagonally glued together with a polyurethane adhesive in a cross section of 90 x 90 mm. Due to complete wood core removal, the wood is much harder and more resistant to weather changes than wood with a wood core circular cross section. A big radius of bevelled edges secures the safety of the users. The wood is protected by pressure impregnation and varnished with two layers of oil paint in shades of brown. To manufacture ladders and platforms we use a board of 35 mm in thickness and 100 mm in width, featuring fluting on one side to form an anti-skid surface.

zinc-coated screws with a raised countersunk head or a hexagonal head with bolsters and nuts; fastening elements are sunk into the wood and protected by covers. Bars, ladders and the components used for attachments are made of spray-coated tubes of 25-35 mm in diameter. The hinge joints for the swings are made of zinc-coated construction steel or stainless steel. Technical chains have a link size of 6 mm, and are made of construction steel (zinc dipped) or stainless steel.

Plastic slides are made of LLD-PE and painted. The advantage of these products is their high rigidity and resistance to atmospheric actions and UV radiation. This version is characterized by its extraordinary resistance and the excellent quality of the slide surface. The slides are assembled up to a height of either 1.2 m (big) or 1.0 m (small).

two methods are used to fasten components to the base. The first method /BASIC/ lies in embedding a wooden beam directly into the ground (50 cm in depth), while being secured by a 30 cm layer of concrete around the beam. The second method /STANDARD, PREMIUM/ makes use of steel bonding ties, thus significantly extending the life-time of the equipment and protecting the wood against the process of decay and decomposition which occurs when wood is placed in earth. The bonding ties are made of 60 x 30 mm steel. The base plate is 150 x 150 mm. The bonding ties are either zinc-coated or spray-coated.